By: Lenindy Devi Soraisham

Okra (Abelmoschus esculentus), “Balendri” in Meiteilon, is cultivated for the ‘okra fruit’ but the stems are being wasted annually after harvesting the fruits. In India, an estimated 4.5 Mt of green okra plants is discarded annually as agricultural waste, which contributes to global warming and pollution. The okra plant has the potential to produce 150–160 kg of okra fibers per hectare and about 13.4 million kg of okra fibers annually, which will give extra income to farmers and helps in curbing global warming and pollution to some extent. Okra plant can play a very important role in circular economy which is very in need to reduce carbon footprint and it can be an important source for doubling farmer income in India. It doesn’t only give its fruit but its stem is also an abundant source of natural fibre. The biomass from the okra plant is biodegradable, cost-efficient, renewable and low-density source for production of bast fibers, and other industrial cost-efficient eco-friendly materials. Due to effect from the synthetic fibres, scientists are trying hard to bring out the same benefit from the natural fibre which is more environmental friendly in nature. There are several other bast fibres which place a great role in the textile industry. Some of them are ramie, pineapple, banana, coir, sisal, etc. One of them is okra fibre that contains good fibre properties in it.

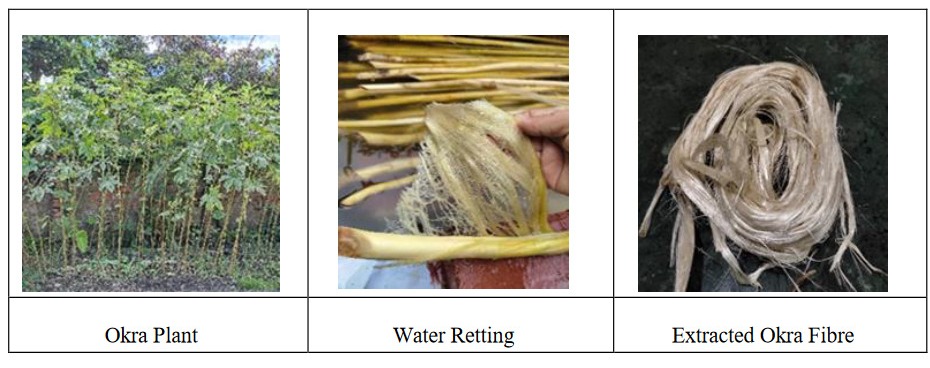

Extraction of Fibre -Water retting method

The okra fibre can be extracted either by water retting, dew retting or chemical extraction. One of the most versatile, efficient, economical, easy and commonly used extraction method is water retting which can be performed on lakes, ponds, tanks and slow moving streams and rivers (these water bodies will be referred as pond afterwards) where the bacteria present in the water degrades the pectin and releases the fibers.

After the harvesting of the okra fruit, the okra stems were collected and tied together in a bunch and immersed inside the pond for 15 to 16 days. The stalk bundles would be weighed down with stones or with heavy woods in order to submerge properly into the water body. Then, the disintegrated fibres were removed and washed properly in running water by rubbing gently until the gummy substance present on the fibre were fully removed and the fibres were let to dry completely in the shade as drying in direct sun will deteriorate the strength and color of the fibre to some extent. The best okra extraction season is during the summer and during winter it takes longer time. The yield of the fibre extracted may be between 10- 25% of the weight of the plant on

dry basis depending on the growth of the okra plant, types of okra plant and type of water bodies that will be utilized for the retting process.

Okra: a silky Fibre

The okra fibre is also shiny and silky in nature which slightly resembles the silk fibre with good breaking strength and elongation. This fibre is also categorized under lingo-cellulosic bast fiber containing high cellulose like other bast fibre such as hemp, ramie, sisal, banana, etc. The main chemical constituents of okra fibre are cellulose (60-70%), hemicellulose (15-20%), lignin (5-10%), along with pectin, fats and wax. The fibre also possesses good mechanical and insulation properties. Depending upon the species, climate condition, soil, geographic location and the extraction method, percentage of chemical constituents may vary which further affects the fibre structure and its properties. This agro waste fibre can be utilized in various textile area depending on the end product. Till date, few studies have developed biodegradable composites, handmade paper products, woven fabric, non-woven fabric, and other textile related products. The yarns of 100% okra fibre is hard to develop as it has less elasticity but yarns can be produced by blending with both the natural and the synthetic fibres like cotton, jute, nettle, polyester, etc.

India is one of the largest okra producer in the world. So, by cultivating the okra, Indian farmer can gain additional income by extracting the potentials from the waste and which will also lessen the environmental menace caused by the agricultural waste. Extraction of fibre from okra can generate positive environmental benefits, thus contributing to the sustainable development in agricultural field which in turn creates dual benefit from single crop. Knowledge among the farmers about okra fibre is in nascent stage and the State Agriculture department along with Krishi Vigyan Kendras should take up awareness program to spread this idea of circular economy i.e. conversion of okra waste to wealth in large scale.

(The authors is Ph.D. Scholar & Dr. Nabaneeta Gogoi, Professor and Senior Scientist Dept. of Textiles and Apparel Designing, College of Community Science, Assam Agricultural University, Jorhat-13, Assam)

Okra: A story of waste to wealth

189